PhotoGraV applies a simultaneous smoothing and edge strengthening to the image.

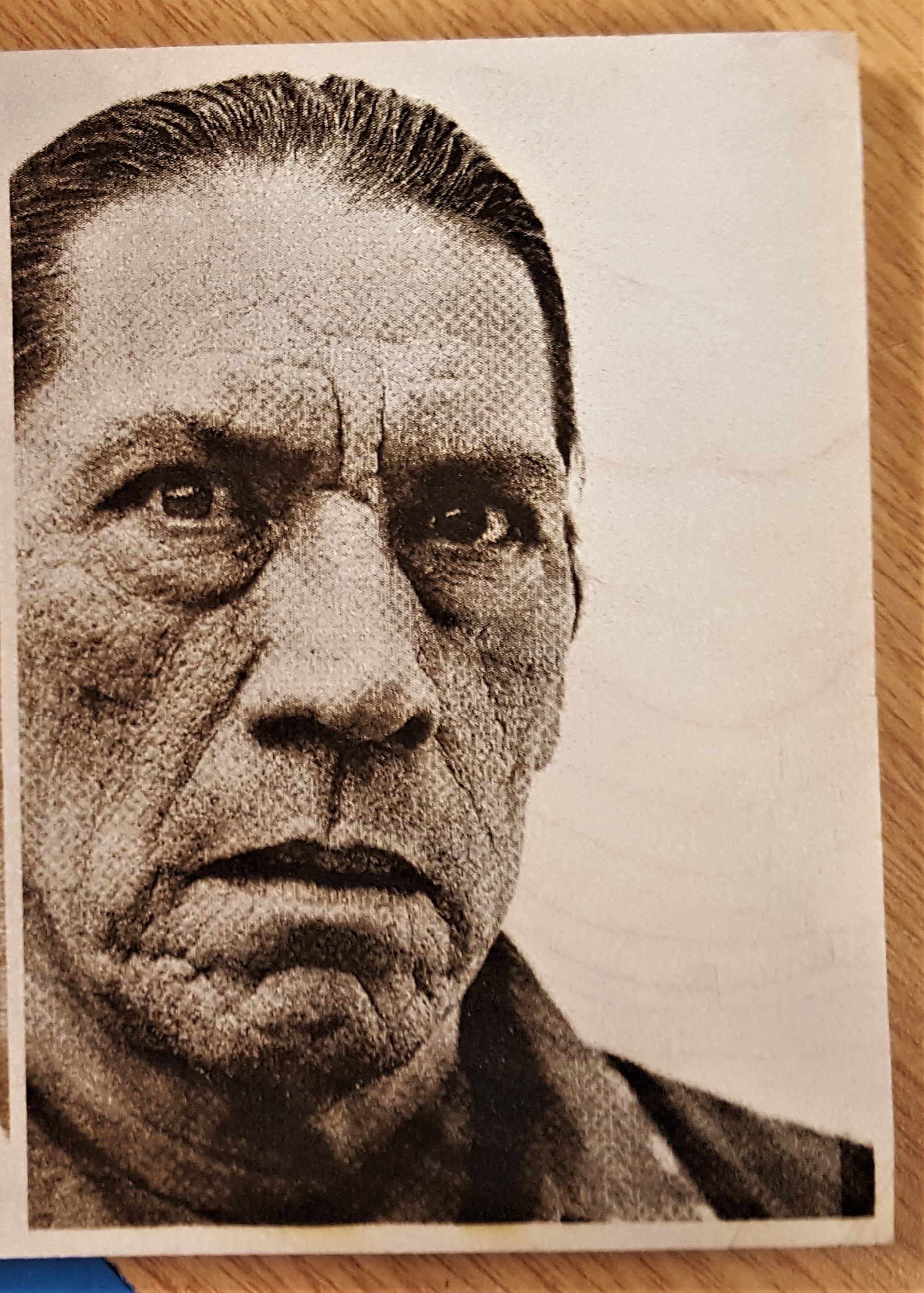

PhotoGraV automatically "stretches" an image's grayshades over the entire grayshade range but also provides user-controlled adjustment of clipping and gamma parameters and histogram equalization in the interactive mode. Other common halftone patterns are also provided by PhotoGraV in a user-adjustable form but, for most images and materials, these "standard" halftones are not nearly as powerful as the adjustable diffusion dithering.Īlthough the following two functions are provided by other graphics programs, only PhotoGraV allows you to adjust the functions' parameters and see the effect on the simulated engraving in near real time. The adjustable density of the diffusion dithering is in addition to the more standard grayshade adjustments that are also provided by PhotoGraV. Further, the density of the diffusion dithering is user-adjustable and has been optimally pre-tuned for the engraving materials supported by PhotoGraV. PhotoGraV provides a diffusion dithering process that has been designed specifically for laser engraving. PhotoGraV's simulated engraving is not merely an overlay of the input photo on a simulated engraving material but rather is produced by a Power/Lens model using the actual binary image that you would eventually send to your engraver. Further, PhotoGraV's interactive mode allows you to adjust any of PhotoGraV's processing parameters and to see the resultant effect on the simulated engraving in near real time (a second or two). PhotoGraV's simulation capability provides a way for you to inspect the appearance of the final product before you actually engrave it. PhotoGraV provides a significant number of advantages over general purpose graphics programs for laser engraving photographs: PhotoGraV solves all these problems and more. If you have tried lasering some of the Corel art, you may be aware of some of the problems 'hidden' lines vector cutting in surprising areas, poor contrast in different colored areas, poorly defined edges, loss of detail, coarse dithering, funny checked patterns, unpredictable shading and depth, etc. Now you can offer any of the thousands of Corel images to your customers with confidence that the final engraving will be wonderful, and you will not have to spend hours tweaking the art and possibly scraping materials. A few simple steps and processing with PhotoGraV will yield spectacular results. Laser engraving the clip art from the CorelDraw collection 'as is' produces less than desirable results, many times engravings are totally unacceptable. Simulation is a powerful tool that saves you valuable time and materials.Įxample: Cherry Engraving Simulation Image Before PhotoGraV, you could not inspect the final product without actually engraving it, a costly and time consuming process.įurther, without PhotoGraV's simulation capability, the effect on the final engraving of any adjustments to the image are difficult to predict. Shown below is the engraving simulation as you would see it in the PhotoGraV software.Īs you can see, the real engraving shown below matches closely the PhotoGraV simulation. The engraving simulation is one of the many powerful features of PhotoGraV that enables you to inspect the "engraved product" before it is actually engraved. PhotoGraV engraving simulation on black brass.

0 kommentar(er)

0 kommentar(er)